The hopper outlet length along feeder can be up to 7 to 8 meters in favourable situation lesser the feed zone length more favorable is the situation for belt life. The material quantity extracted from the hopper.

Considerations In Belt Feeder Design Operation

The need for feeders and mass-flow hoppers to be designed as an integral unit to promote uniform feed is emphasised.

. Hoppers Bins Silos Manufacturer Hoppers are similar to bins except with an open top Storage capacities up to 10000 cubic feet can easily be handled with hoppers bins and silos Kase hoppers bins and towers are used in the frac sand cement chemical mining and aggregate industries for storing many bulk materials. Books about BELT FEEDER DESIGN AND HOPPER BIN SILO. Mechanical Formerly Head of Project Engineering dept.

Author of Book. Depending on silo or hopper design it can be recommended at times to retain some product in the silo or hopper to minimise high initial bin filling loads. C-1204 Nikash Lawns Sus Road Pashan Pune-.

Model 101 30R RAPShingle Bin Feeder. CONVEYORS Design fundamentals for drive Know More. Video explains how to design a hopper feeder belt conveyor drive.

Belt feeder design thus needs to consider all specific requirements determined by the material being moved as well as capacity and geometry. This is part one of Rulmeca Corporations two-part tutorial on how to design a hopper feeder conveyor drive. Belt feeder design and hopper bin silo pdf - Gold Ore Crusher.

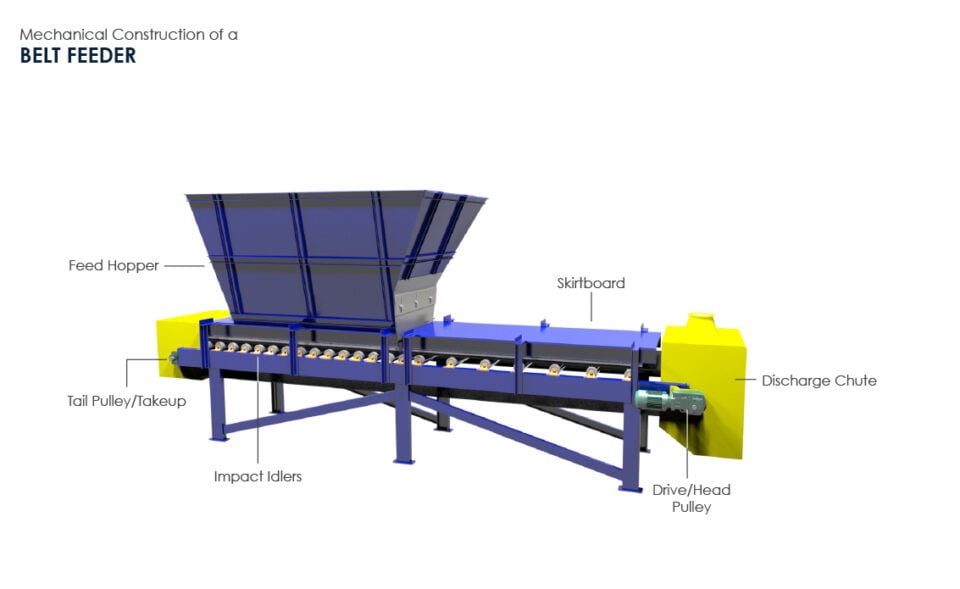

The basic design features of belt and apron feeders is presented. Krupp-India Write Communicate on following address to get buy this book. Belt feeder hopper design Written By carrollmees23725 Wednesday April 27 2022 Add Comment Edit.

Belt Feeder is placed bellow the hopper and it is designed to work flooded of material and take out only a required quantity of material in m3sec. Stone Hopper Belt Feeder Design Drawings. Depending on silo or hopper design it can be recommended at times to retain some product in the silo or hopper to minimise high initial bin filling loads.

Calculated taper in both plan and elevation to achieve uniform material withdrawal a slanted nose andor an arch-shaped lip to provide stress relief and prevent stagnation at the discharge end a flexible rubber or plastic buffer at the back end to allow a typical half-inch gap for uniform material. Vibrating Feeders Belt Feeders CementLime Silos Mixing Blending. Design techniques such as tapered openings by 5 degrees divergence and relieving the feeder angle by a few degrees assists with minimising pull-out torques.

For a free copy of the power calculation program go to. The essential requirement is to promote uniform feed with the whole of the hopperfeeder interface active. BHT Belt Feeders are designed and manufactured to ensure long life and reliable service in the harshest of operating environments.

This lecture includes three parts. The belt feeder center to center distance is. The belt feeder design cannot be done unless the pressure values at interface are known.

By design this feeder Polyurethane Timing Belt Non-Mar Conveyors Hopper Feeders Model 2000300036004800 Hopper Feeders are used for feeding. Belt feeder design and hopper bin silo pdf 2 storage Springer Link belt feeder design and hopper bin silo pdf The design of bins hoppers and silos has never been given the attention it deserves by and hopper walls and on the feeders and chutes under operating conditions. The loading of bulk solids onto belt conveyors.

The need for feeders and mass-flow hoppers to be designed as an. BELT FEEDER DESIGN And HOPPER BIN SILO By ISHWAR G. Hopper Feeder Design - Products - Machinery.

The belt feeder can extract the material from hopper outlet. Our mechanical and structural engineers have decades of experience in the design and manufacture of custom belt feeders and hoppers to suit a wide range of materials and feed rates. Belt Feeder Design and Hopper Bin Silo Advisor Consultant for Bulk Material.

A separate video will be present arching theory calculating hopper drag load and pressure relief tips. The major features of this design are. The purposes of hoppers standard conveyor belt loads and special hopper loading.

In this article we discuss proper belt feeder design technique so as to maintain reliable flow from bins and hoppers Belt feeders are used to feed many types of bulk solids F 4 - Otto von Guericke University Magdeburg How to Design the Best Bin Silo Hopper or Feeder An improperly designed silo bin or hopper can be fixed but the. Contract Design Service Inc. Correct conveyor drive design can be a similar fashion to a belt feeder hopper conveyor does not feed onto the other.

Posts Related to belt feeder design and hopper bin silo pdf. Capacity of a belt feeder can be increased by tapering the outlet in theFarm Hopper Tanks BFT GHT. Pugmill CTB Plants BlendingCold Feed Bins Model 101 48 Front End Loader Hopper with 48 Belt Inventory Number.

Hopper details hopper type - plane flow 0m hopper half-angle 25 centre for bulk solids hopper opening dimension s 125 m hopper width at transition d 55 m participate technologies height of hopper section z 45 m length of hopper opening l 625 m the centre for bulk solids particulate technolo- feeder details gies is. Model 101 30RG RAPShingle Bin Feeder with.

Hopper Conveyors Steel Belt Feeders Crsni

Hopper Feeder Drive Design Part 1 Of 2 Youtube

How To Design A Belt Feeder Interface Powderbulksolids Com

Considerations In Belt Feeder Design Operation

Conveyor Belt Feeder 3d Cad Model Library Grabcad

A Fundamental Approach To Belt Feeder Loads How To Assess Loads On Feeders Practically Fig 2 Bulk Blog

0 comments

Post a Comment